QUALITY CONTROL

ELİN A.Ş. tests in-house the tempered glass, cells, eva, backsheet, copper conductor wires (ribbon, busbar), terminal boxes, silica gel (potting and frame, terminal box adhesive), frames, flux that is used in brazing and similar materials in accordance with the Input Quality Control (GGK) standards. No materials not conforming to the GKK Standards are accepted into the production. The accepted materials are stacked in the special air conditioned material room.

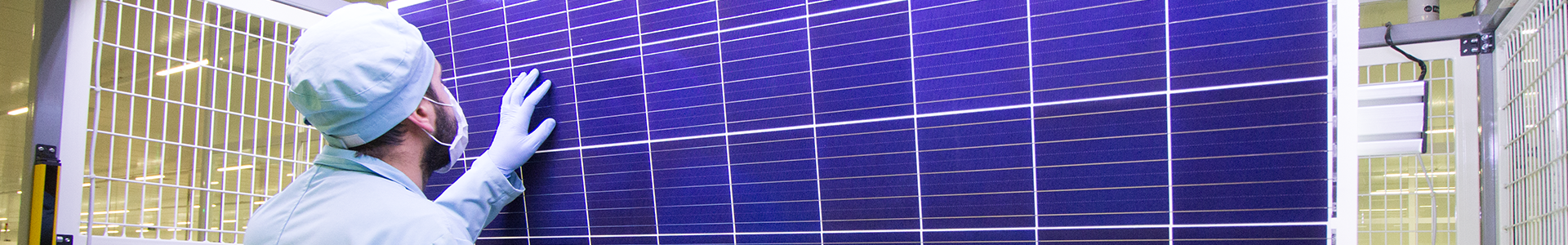

During production phase, each process is checked according to the Process Quality Control Standards. According to the images of the Electro Luminescence (EL) test that is the first quality control point, the conforming panels receive lamination process.

After lamination process the second important quality point, Visual Control is performed. In this process the visual conformity of the panels are checked. Then the frame is set and the terminal box is installed. After potting silicon is poured on the terminal box, the panels are taken to the special air conditions "Curing Room" established in-house by ELİN A.Ş. to wait.

After all these process the power of the panels are measured in Standard Test Conditions (STC) (1000w/m2; 25oC temperature; 1.5 AM) and labeled. Then in a second Electro Luminescence (EL) Test the final images are recorded and they are sent to packaging.

ELİN A.Ş. checks the panels meticulously at every stage of the production and performs the Liquid Impermeability Test via sampling method that is mandatory under the scope of IEC 61215 standard and records the results. Also, in order to test the Eva-Glass-Backsheet conformity, Adhesion Test, and to test the quality of the Cells Peeling Test, for the conformity of the Evas used on the Front and Back surfaces of the Glass Cross Linking Test, for the Terminal Box Plotting A/B Silicon Mixture Ratio Tests are performed.

Moreover, in order to increase the reliability of our panels, tests on panels and Factory Production Control (FPC) are performed by 3rd party institution TÜV, TSE, KİWA.

EN

EN TR

TR NL

NL DE

DE